TaipeiPLAS 2022 聚焦 智慧製造 創新應用 淨零永續 三主題。

睽違4年實體展的「台北國際塑橡膠工業展(TaipeiPLAS)」,將於今( 2022)年9月27日至10月1日在南港展覽1館與「台北國際製鞋機械展(ShoeTech Taipei)」同期舉辦,並搭配1個月的線上展實虛併進開展。今年TaipeiPLAS聚焦三大主題–「智慧機械」、「新世代材料」及「循環經濟-淨零碳排」,主辦單位外貿協會從開展前倒數3個月起,逐月推出「智慧製造」、「創新應用」、「淨零永續」主題月,6月「智慧製造」主題月率先登場,從社群、電子報與影音內容等,帶領海內外買主提前感受本次展出各項亮點。TaipeiPLAS 2022國內外參觀預登並隨主題月的推出同步開放,也提供主題月電子報訂閱,想獲得TaipeiPLAS第一手展訊的業者,千萬不可錯過!

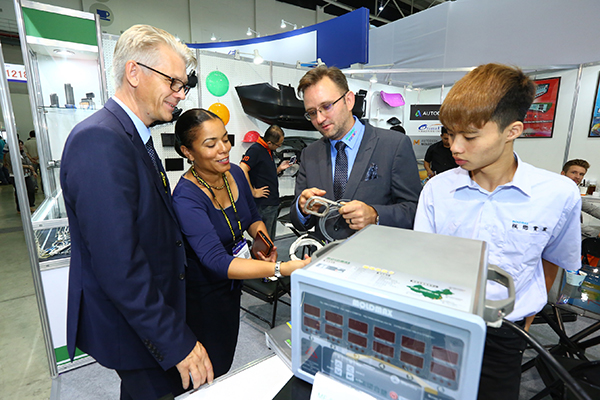

至於選擇6月首推智慧製造,外貿協會表示,因為對塑橡膠機械而言,過去塑橡膠製造加工業在模具參數的設定與調整、材料的選擇、複雜元件處理,往往必須仰賴經驗豐富的師傅操作與判斷。現今因應生產智慧化、自動化與客製化的浪潮,塑橡膠機械有了智慧製造的加持,並結合產線自動化、智慧感測、遠端監測等先進製造技術,新型態生產與商業模式已完全顛覆產業樣貌,讓塑膠聰明成型。

以本次TaipeiPLAS參展廠商,也是臺灣塑膠射出成型機的指標廠商富強鑫及鳳記為例,導入整合生產製造執行系統MES(Manufacturing Execution System)讓機台生產流程全程數位化,品質管理與控制更加精確,達成提升生產效率、降低生產成本等多重效益。且不光自己變得更聰明,臺灣塑橡膠機械廠商的成功經驗也輸出海外,提供海外客戶整廠自動化的規劃及整合服務。

其他指標廠商如百塑、鼎坤、一億、映通,以及國際大廠BASF、ARBURG、WITTMANN BATTENFELD、ENGEL等,也將齊聚今年TaipeiPLAS,展示各項智慧機械與智慧製造加乘的最新研發成果。而為呼應今年TaipeiPLAS「Shaping New PLASbility塑造新未來」的核心主軸,展中外貿協會也將推出展場直擊、Podcast、主題式導覽、專業技術論壇等多元活動,深入探索塑橡膠產業的發展與蛻變,創造耳目一新的參展體驗,歡迎各界共襄盛舉。

活動報名請洽舊金山台灣貿易中心,Email: sf@taitra.org.tw,更多有關2022年TaipeiPLAS及ShoeTech Taipei展覽最新訊息及線上線下活動詳情,請鎖定官網www.taipeiplas.com.tw/www.shoetech.com.tw及社群粉絲頁。

TaipeiPLAS launches pre-show monthly campaigns featuring Smart Manufacturing, Innovation, and Sustainability

Taipei, June 2, 2022: The physical edition of TaipeiPLAS is scheduled to return from September 27 to October 1 this year at Taipei Nangang Exhibition Center, Hall 1 (TaiNEX 1) in conjunction with ShoeTech Taipei. A month-long online exhibition will continue till October 27. This year’s TaipeiPLAS focuses on three major themes – “Smart Machinery,” “Next-gen Materials” and “Circular Economy – Net Zero Carbon Emissions.” Starting from June, the organizer, TAITRA, launches monthly theme-based campaigns to unveil the highlights of the coming TaipeiPLAS with social media news, exhibitor & production introductions, e-newsletters and videos. E-newsletter subscription and visitor registration are both now available on the official website.

The pre-show monthly campaigns for the show kick off with the first theme “Smart Manufacturing” in June. The plastics and rubber manufacturing has become greatly different from what it was, says TAITRA. In the past, the manufacturing processes of plastics and rubber such as the parameters setting, the material selection, and the processing of complex components relied on the operation and judgment of experienced labor. The smart manufacturing technologies today have turned the production line to be fully automated, more efficient, meanwhile, led the industry to create new business models.

Key industry players from home and abroad such as ANN TONG, ARBURG, BASF, DIING KUEN, ENGEL, FKI, FSC, MULTIPLAS, WITTMANN BATTENFELD, YEI all gear up to make a splash at TaipeiPLAS 2022 by presenting their smart machines and smart manufacturing solutions. FCS and FKI for example, the two leading plastic injection molding machine manufacturers in Taiwan have integrated Manufacturing Execution System (MES) into every section of their machine production and assembly lines. Multiple benefits are achieved, including more accurate production control, improved quality management and production cost reduction. Taiwan plastic and rubber machinery manufacturers are transforming to become smarter, and at the same time, providing a full line of services in building smart production lines overseas.

Besides onsite and online exhibition, TaipeiPLAS 2022 will come with a lineup of seminars, forums and featured events, On-site Guide for Online Visitors, PLASpotlight Live, themed guided tours, and procurement meetings, all together to explore the innovative trends in plastic and rubber industry and also to create a refreshing exhibition experience.

Please contact Taiwan Trade Center, San Francisco at sf@taitra.org.tw for free event registration. For more updates and full events information, please visit the official websites, or follow the shows on social media.

TaipeiPLAS 2022:www.taipeiplas.com.tw /.

ShoeTech Taipei 2022:www.shoetech.com.tw